Features

Our full-service aircraft modification center features:

- More than 430,000 square feet of hangar space, and the ability to accommodate aircraft of all sizes, from small rotor-wing aircraft to widebody jets

- A modern strip and paint facility, capable of painting widebody jets

- Full complement of backshop and manufacturing capabilities

Aircraft Operations - Manufacturing Capabilities

Our experienced workforce includes a full-range of engineering talent, including all disciplines necessary for aeronautical programs and highly skilled A&P-licensed aircraft mechanics and electricians.

Our M3 facility has a full range of Hangar, Dock and Line, manufacturing and assembly capabilities to support all aircraft operations. Manufacturing capabilities include:

- Sheet metal fabrication

- Machining fabrication

- Finishing shop

- Mechanical assembly

- Electrical assembly

- Cable and harness assembly

- Electrical testing

- Fiberglass and composite fabrication

- Graphics fabrication

- Cabinet shop

- Rapid prototyping

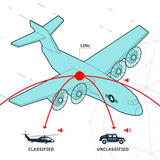

U.S. Navy P-8A Fleet Readiness

This partnership ensures the Naval Air Systems Command (NAVAIR) fleet of 135 P-8A Poseidon aircraft remain mission ready. We are a proven leader of sustainment and modification support on the P-3 Orion – the predecessor platform to P-8 – across multiple customers, including the U.S. Navy and NOAA and to the militaries of Brazil, New Zealand and Republic of Korea. Our team is providing integration and sustainment solutions for U.S. Navy’s mission success:

- Airframe Depot Maintenance

- Repair and Overhaul (MRO)

- Concurrent modifications and technical directives