Product Specifications

At L3Harris, we guarantee excellence at every stage of production in our mechanical manufacturing area to support our government, military and commercial customers. Our employees are trained and equipped with the best tools to fabricate, assemble, process and finish virtually all of the components of your product.

Sheet Metal Fabrication

Among our many process capabilities are the latest in combo laser/punch press technology, CNC routing, CNC Water Jet, CNC brake form, hydro form, roll form sheet and aluminum heat treatment. We also process a wide variety of honeycomb sandwich materials to fabricate lightweight components such as floorboards, panels, table tops and rack and/or console components.

Machine Shop

Three, four and five-axis machining, as well as high-speed machining over 30,000 rpm allow machining of any family of parts up to 5ft x 12ft in size. On-site CNC turning centers and specialty tool grinding expand our capabilities, while integrated CAD-CAM systems and computer-based digital inspection systems ensure accuracy in each job.

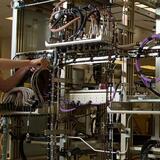

Mechanical Assembly

L3Harris technicians' mechanical crews assemble a wide range of assemblies and subassemblies full spectrum of avionics structures, including aircraft structure subassemblies, antenna mounting structures, cockpit equipment frames and avionics mounting racks, and also modify existing racks and structures.

Quick Response Cell

The quick response cell (QRC) functions both as a stationary and portable machine shop. We exist primarily to provide quick response in reverse engineering and modification of existing aircraft components. Our QRC cell team responds quickly to tubing fabrication, oxygen tube fabrication and cleaning, gas tungsten arc welding, match drilling and onboard aircraft machining needs. This highly skilled QRC team ensures that your product is completed to the highest standard of quality in the shortest time possible.

Chemical Processing/Finishing

Chemical processing and finishing capabilities include conversion coating (alodine), steel passivation, painting, part identification and engraving.

Composite Shop

Our composite shop is capable of working wet-laminate or pre-preg fiberglass, graphite, and kevlar, in addition to composite repair, sandwich panel construction, vacuum thermoforming, structure metal bonding and hot bond repairs. Multiple curing ovens allow processing of products up to 10ft X 20ft X 9.5ft in size.

Tooling/Metrology

Tooling shops manufacture assembly and installation tools and fixtures as well as molds and form blocks to support product manufacturing and assembly processes. Reverse engineering through photogrammetry, CMM, and cutting edge later tracker technologies ensure precise component placement, aircraft alignment, tooling positioning, shoring, and direct feature location.