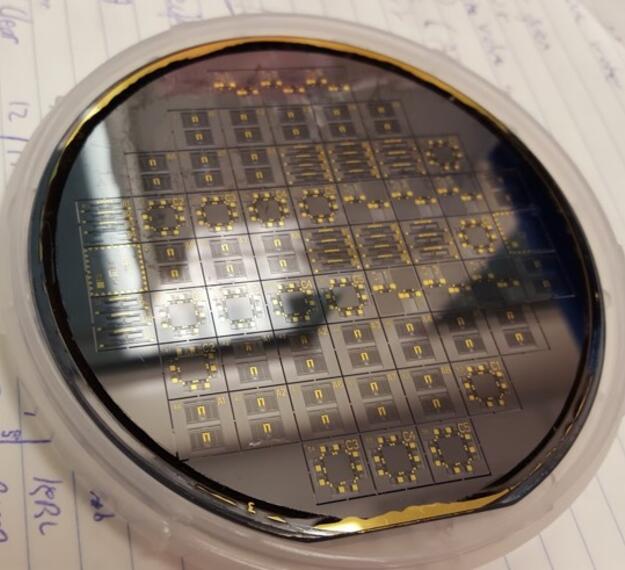

Micro-Nano Rapid Prototyping

L3Harris process engineers working at government-funded state-of the-art cleanroom facilities provide the unique ability for inexpensive fully in-house rapidly developed solutions from chip-level die design to wafer-level packaging. Turnaround time as quick as one week compared to foundry often requiring six months or more at three times the cost.