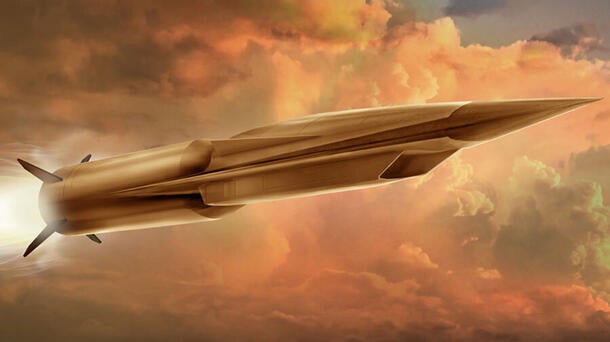

More than 14 years have passed since the first X-51A WaveRider—powered by a supersonic combustion ramjet (scramjet) engine built by Aerojet Rocketdyne, now a part of L3Harris Technologies—made hypersonic history by completing the longest-ever supersonic combustion ramjet-powered flight.

Industry has made significant advances in the field in the years since, demonstrating we have both the propulsion technology and the production capacity to support fielding operational hypersonic systems to deliver their capabilities into the hands of our warfighters. L3Harris demonstrated its scramjet technology with the Hypersonic Air-breathing Weapon Concept (HAWC) program and is continuing to advance 3D-printing technology through programs such as GAMMA-H.

When the Defense Department released its National Hypersonics Initiative 2.0, guiding the nation’s collective approach to fielding operational hypersonic systems, a former DOD Principal Director for Hypersonics noted the need for systems to be, “built affordably and at high rate to meet the needs of the warfighter as well as continuing to evolve our technology.” The initiative includes four main pillars that aim to accelerate hypersonic technology development in an affordable, responsible and robust manner.