L3Harris’ Calzoni business recently marked a significant milestone for the company, celebrating 190 years in Italy’s naval industry. Calzoni – which was founded in 1834 in Bologna, Italy – became a part of L3Harris’ Undersea Systems division in 2012, further strengthening L3Harris’ position as a global company and the Trusted Disruptor in the defense industry.

Calzoni has developed a strong relationship with the Italian Navy and other major navies around the world. The company specializes in providing integrated sensors and payload handling systems for submarines and surface ships, as well as visual landing aids.

L3Harris has a well-established presence in Italy, employing over 230 people. As a significant player in supporting both current and future naval programs, L3Harris' involvement in Italy's naval industry is both strategic and impactful.

A Story of Knowledge and Innovation

The Calzoni story is one of knowledge and innovation that began in Bologna, Emilia Romagna, Italy in the mid-19th century and has since evolved around the world.

The company’s evolution can be summarized in four key words: people, technology, efficiency and innovation.

L3Harris’ Calzoni story begins with the visionary ideas of engineer Alessandro Calzoni, who applied the principles of oleo dynamics to agriculture – an innovative concept at the time. By World War I, the company shifted its focus to defense, supplying oleo dynamic systems to the Italian Royal Navy for use in submarines. Most notably, the company was the first to introduce non-penetrating submarine mast-raising equipment in the 1960s.

Since the late 1990s, L3Harris, particularly its Calzoni site, has been a key supplier to the U.S. Navy, driven by strong partnerships, continuous innovation and improved process efficiency.

L3Harris' main facility in Italy is in Calderara di Reno, Bologna, spanning 11,000 square meters. The facility is equipped to handle the entire development process for submarine equipment, from design and machining to assembly and final testing. As a result, it can provide customers with customized, turn-key solutions.

In June 2023, the company expanded its production capacity by opening a new 5,500-square-meter production facility in the same area. This new facility is designed for the assembly, testing and qualification of visual systems, unmanned vehicles and ship handling systems.

Additionally, the facility includes a service center dedicated to maintenance and customer support for products provided by other divisions of L3Harris. It also serves as a WESCAM Authorized Service Center.

190 Years of Innovation: A Journey of Success Driven by Talent

From the beginning, human talent has been the driving force behind Calzoni’s growth and success. Innovation and technology from its talented workforce has distinguished the Calzoni business. In the past 20 years, the company has more than tripled in size and developed solid investment and growth plans for the coming years. Its systems are now installed on board ships and submarines for over 40 navies around the world.

The business is a market leader and key innovator in handling systems, snorkels, gas exhaust systems, and air inlet valves used on submarines, as well as visual landing lights for helicopters. The extensive product offerings span both submarines and surface ships.

Over the years, the company has focused on developing solutions that allow clients to operate safely while keeping their staff protected, utilizing remotely operated and autonomous systems.

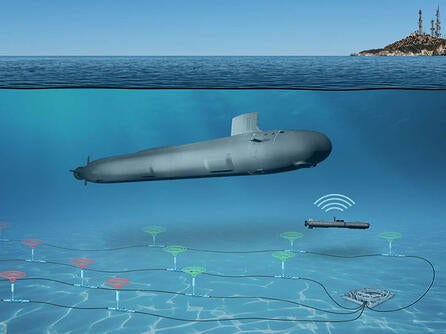

One example is the Hunterwater™ project, an innovative "system-of-systems" featuring an advanced unmanned surface vehicle that measures 7.5 meters in length. This platform is equipped with several unmanned vehicles, including the Rovscan—a next-generation remotely operated vehicle that incorporates side-scan sonar and an integrated launching system. The design allows for expansion with the Iver AUVs, another innovation from Calzoni, which facilitates large-scale maritime surveys to identify and classify potential targets. Once targets are detected, Hunterwater takes the lead in their identification and neutralization.

To enhance the capabilities of maritime platforms, Calzoni recently developed the Zero Human Intervention Automatic Guided Operation (ZHIVAGO) system—an innovative launch and recovery system that significantly advances automated maritime operations. This system features a uniquely patented architecture that integrates cable robot technology with a dynamic robotic motion system and a lifting mechanism, allowing ZHIVAGO to perform autonomous launch and recovery tasks with unparalleled precision.

The company has been actively developing E-conversion technology, which is a strategic focus for L3Harris and industry partners. Design and testing of various enabling solutions have led to the creation of motors with a power output of up to 350 kVA.

This technology is currently being utilized in three of the company’s ongoing projects: an azimuth thruster for submarines that aids in maneuvering and emergency reentry; a propulsion system designed to have a reduced magnetic and acoustic signature for minehunters; and a set of hoisting actuators with controls and power drives for the new Italian Navy submarines.

As Calzoni celebrates the remarkable milestone of 190 years of delivering innovative technology to enhance the naval industry, L3Harris is committed to being the Trusted Disruptor in the market, modernizing to deliver future capabilities. This dedication, powered by a skilled and talented workforce, establishes a strong foundation for the company’s future.